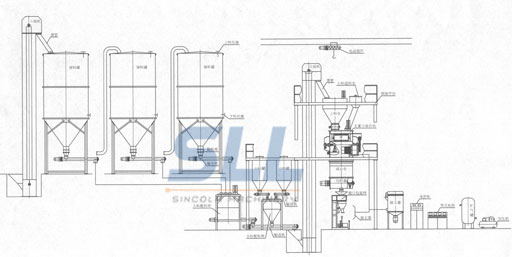

50TPH Ladder type dry mortar production line solution

Application of dry mortar production line

1. Storage silo(carbon steel or stainless steel) mode: raw material silo, mid-silo, finish product silo. The raw material in the big silo can meet many batch , the amount of silo is decided by your requirement .

2. Conveyor (carbon steel or stainless steel) modes: pneumatic conveyor, vacuum conveyor, bucket elevator, pump truck, belt conveyor, manual feeder.

3. Batching / dosing equipment modes (carbon steel or stainless steel): weighing hopper, pneumatic conveying & weighing pot.

4. Mixer / agitator (carbon steel or stainless steel) : double-shaft paddle mixer, helix mixer (ribbon type mixer), coulter mixer, reactor, conical mixer.

5. Packaging equipment (carbon steel or stainless steel): ton-bag (jumbo bag) packaging machine, valve-bag packaging machine, open bag packaging machine (granular or powdery material).

6. Control system: touch screen (siemens, Mitsubishi, etc.) + PLC.

The obvious advantages of this plant is as following:

1.High capacity: pneumatic conveying is obviously faster than bucket elevater , the mixing time for one batch is about 5 minutes, the capacity of packaging machine is about 8-10t/h.

2.Less dust: pneumatic conveying determine the plant with good sealing property, the superiority of pulsed jet cloth filter is that it can release the dust into the product, no wasted material.

3.Less material remains: some material remains in the bottom of the bucket elevater,but there is no such problem in this plant. The high pressure push all the materials into the hoppers.

Application mortars:

1.Masonry mortar

2.Plastering mortar

3.Ceramic tile binder

4.Thermal insulation mortar

5.Heated board matching mortar

6.Gap filler

7.Interface mortar

8.Decoration mortar and powder coating

9.Self-leveling mortar

10.Floor mortar

11.Gypsum joint mortar

12.Waterproof dry-mixed mortar

13.Non-shrinkage grouting material

14.Repair mortar

15.Hardening and artistic floor mortar

16.The maxing brickwork, plastering wall, pasting tiles, floor tiling, stone plate and floor