mortar formula

Advantages of dry mortars

Since dry mortars are pre-mixed at the plant, any dosing and mixing errors can be excluded. This is a guarantee for the production of top-quality products. Since mortars can be applied both manually and mechanically, construction process becomes more rational….

Dry mortar formula

Dry mortar formula

1.Powder particles of polystyrene insulation mortar formula

Ordinary portland cement 42.5 700kg

Quality silica fume 70-105kg

TSP (fly ash and ash calcium powder) 300kg

Condensation copolymer powder 5-10kg

Hydroxypropyl methyl cellulose ethers (HPMC) 5-10kg

Polypropylene staple fiber 2kg

2.glass beads insulation mortar formula

Ordinary portland cement 42.5 150kg

Quality silica fume 15-23kg

Polypropylene staple fiber 0.2-0.5kg

Condensation copolymer powder 2-3kg

Hydroxypropylmethylcellulose 2kg

Glass beads 1 cubic

3 perlite insulation mortar

Ordinary portland cement 42.5 700kg

Quality silica fume 70-105kg

Fly 300kg

Polypropylene staple fiber 2kg

Easily dispersed wood fiber 5kg

Condensation copolymer powder 5kg

Hydroxypropyl methyl cellulose ethers (HPMC) 5kg

4.interior water putty formula

Ash, calcium (325 mesh) 300kg

TSP (325 mesh) 700kg

Polymer nano-powder (flexible type) 3kg

Hydroxypropylmethylcellulose 5kg

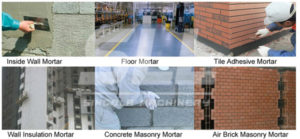

Masonry mortar

Plastering mortar

Ceramic tile binder

Thermal insulation mortar

Heated board matching mortar

Gap filler

Interface mortar

Decoration mortar and powder coating

Self-leveling mortar

Floor mortar

Gypsum joint mortar

Waterproof dry-mixed mortar

Non-shrinkage grouting material

Repair mortar

Hardening and artistic floor mortar